Awards

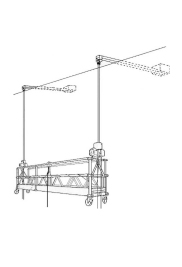

Are you in need of scaffold support for your construction projects? Discuss your specific needs with our professional consultants. Our experienced team can accommodate almost any requirements from simple working platforms and scaffold towers to propping, shoring, formwork and scaffold stages with all the necessary extras like sheeting, temporary roofing, ramps, runways, hoists, fencing and rubbish chutes.

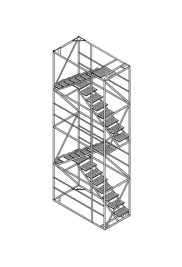

We provide 7 types of scaffolding solutions that can be used interchangeably according to the client’s specific needs and requirements. The site conditions will also determine the type of scaffolding that can be used for the individual projects.

Types of Scaffolding

How we do it

Speak to Our Consultants

Make an appointment to speak to us today for a no obligation consultation or drop us a message on your project for a free quotation on your upcoming projects.